- EMAIL: SALES@CRESSALL.COM

- • TEL: +44 (0) 116 273 3633

DESIGN & TESTING FACILITIES

TESTING & TEST EQUIPMENT

We have calibrated test equipment for all routine testing, including resistance and inductance meters, insulation resistance meter, and dielectric testers rated up to 100kV. For high voltage applications we can conduct impulse testing to 400kV

For high power testing of load banks and brake resistors, we have access to one of the best equipped test laboratories of any resistor manufacturer in the world.

This is used both for in-house development and for routine and type-testing customers’ equipment.

HIGH POWER TESTING

A 1.5kV chopper-controlled DC power source, continuously rated at 1.5MW, enables us to test resistors at full load power and under simulated cyclic conditions. Full scale test results are at the heart of all our design models and enable us to produce designs that are ‘right first time’.

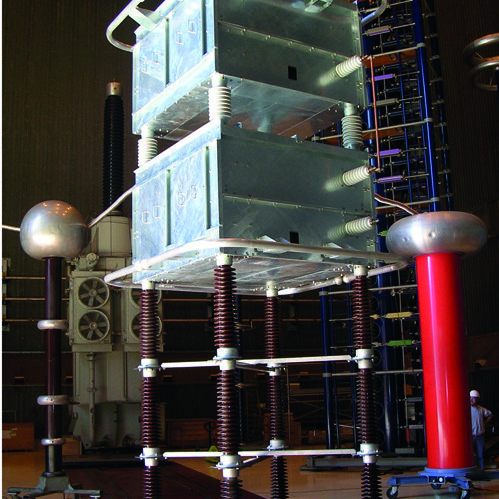

IMPULSE TEST TO 400kV

A 400kV impulse generator which is used for dielectric and through impulse tests.

THERMOVISION EQUIPMENT

A recording thermal vision camera is used to identify hot spots and ensure that designers have an accurate picture of the overall thermal performance of their products, particularly in traction applications where space and weight constraints make good airflow design essential.

VIBRATION TABLE

2M x 2M hydraulically driven vibration table (with vertical and horizontal axes respectively) for vibration, shock and seismic tests. Traction resistor tests are carried out to IEC Standard 60373. We have the capability to carry out dynamic strength tests, long life tests, road simulations and noise level measurements, as well as static and dynamic finite element analysis of resistor structures.

COMPUTERISED DATA LOGGING

The test laboratory is equipped with computer-controlled multi-channel data logging equipment and optically-isolated transducers for high voltage measurement and recording. Test variables such as temperature, power and current are also recorded.

ENGINEERING DESIGN TOOLS & RESOURCES

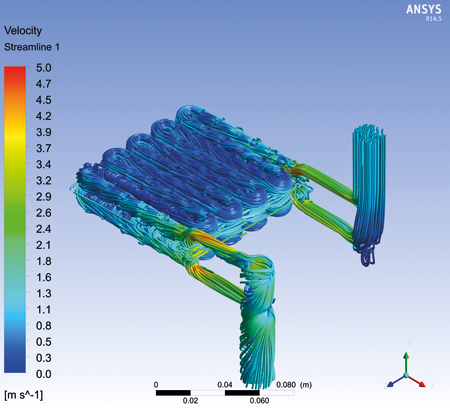

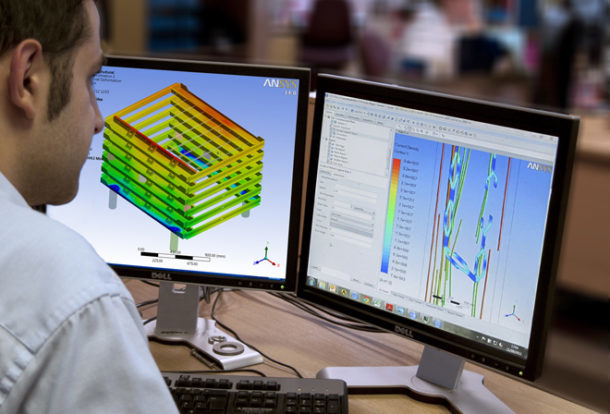

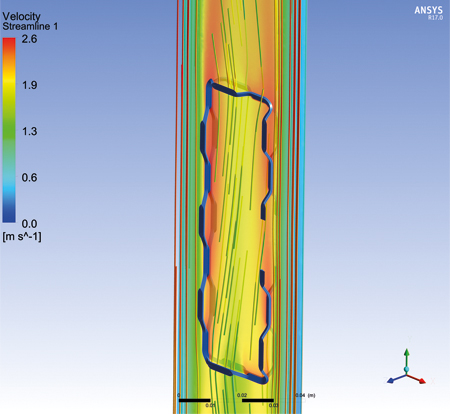

All Cressall’s products are designed, engineered and manufactured at our sites in Leicester and Dereham using the very latest computer-aided design tools such as Autodesk Inventor for 3D modelling and design, ANSYS for thermal, structural, seismic and fluid flow analysis and Radan as the interface with our metalworking machines.

These resources plus a library of more than forty years of proven designs and test data enable us to respond quickly and accurately to new product requests. Designs are validated initially using finite element models derived from past testing and then by full-scale testing when necessary.